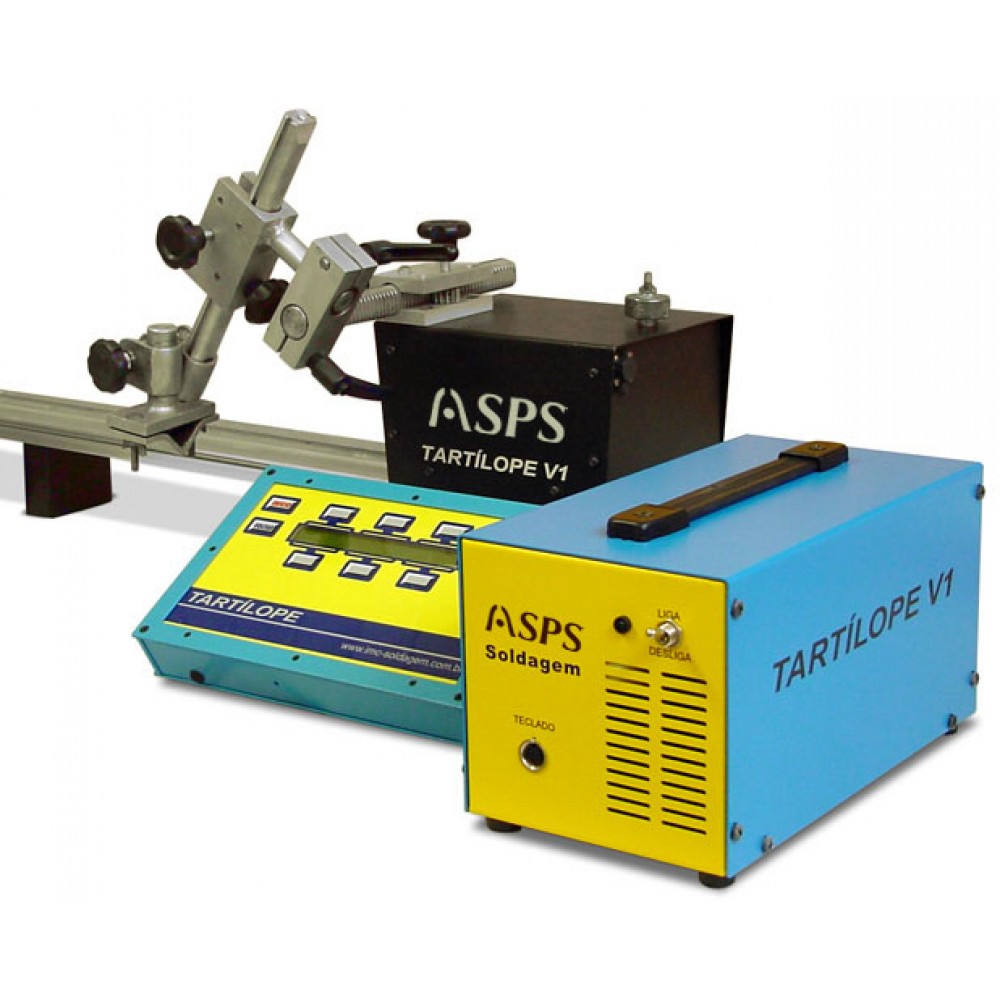

Características do Equipamento

Sistema automático de deslocamento da tocha de soldagem

O Tartílope V1 é um sistema de deslocamento automático de tocha, que permite a realização de soldas e cortes em qualquer posição. A faixa de velocidade de deslocamento varia de 5 a 160 cm/min, com resolução de 0,2 cm/min no ajuste de velocidade, abrangendo, desta forma, os processos de soldagem MIG, TIG e Plasma, oxicorte e corte por plasma.

- Módulo eletrônico microprocessado que processa e controla os movimentos.

- Módulo trator com engrenamento a trilho rígido (os trilhos podem ser fixados em qualquer posição por fixadores magnéticos ou por ventosas).

- Módulo de fixação de tocha com ajustes manuais.

- Controle remoto de programação.

Repetitividade de processos

O Tartílope V1 proporciona repetibilidade de processos, ou seja, o movimento executado uma vez poderá ser repetido com fidelidade quantas vezes forem necessárias.

Unidade de controleO equipamento possui uma unidade de controle eletrônica micro-processada e interface homem máquina com display de cristal líquido que proporciona agilidade no manuseio do sistema. |

Dispositivo mecânicoO dispositivo mecânico do Tartílope V1 se movimenta sobre um trilho rígido de alumínio com 1,18m de comprimento. Os trilhos podem ser encadeados de forma a permitir soldagem ou cortes de grandes extensões. |

Suporte de tochaO Tartílope V1 possui um suporte de tocha que permite a regulagem manual da posição lateral, vertical e em ângulo, possibilitando diversas configurações de posicionamento para a operação com diferentes tochas de soldagem e corte. |

A SPS desenvolve sistemas para soldagem, automação e instrumentação, atendendo setores como:

- Ensino e Pesquisa;

- Óleo e Gás;

- Construção Naval;

- Papel e Celulose;

- Mineração;

- Energia;

- Agricultura;

- Farmacêutica;

- Alimentícia;

- Bens de Consumo.