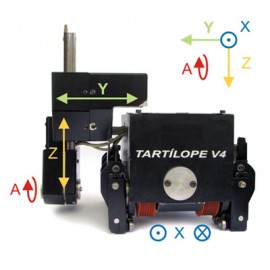

O Tartílope V3/V4 é um sistema de deslocamento automático de tocha, que permite a realização de soldas e cortes em qualquer posição, com deslocamento automático em três ou quatro eixos.

Características do Equipamento

Sistema de movimentação automática para soldagem com três ou quatro graus de liberdade

O Tartílope v3/V4 é um manipulador robótico para soldagem que possui movimentação automática em até quatro eixos, permitindo que o equipamento reproduza os movimentos necessários para executar tarefas de soldagem de elevada complexidade.

Apesar da grande versatilidade proporcionada pela movimentação em três ou quatro eixos, o equipamento possui pequeno peso e volume, sendo facilmente manipulado e transportado, ideal para aplicações em campo.

O trilho pode ser rapidamente fixado e removido do local da soldagem utilizando-se um conjunto de sapatas magnéticas. Também, é possível customizar a fabricação dos trilhos e sapatas magnéticas de acordo com a aplicação, como por exemplo na soldagem de revestimentos de paredes de tubos de caldeiras para geração de vapor.

- Módulo eletrônico microprocessado - processa e controla os movimentos

- Manipulador da tocha - permite a interpolação dos eixos que se movimentam simultaneamente para descrever trajetórias complexas

- Interface homem-máquina - permite a programação e configuração do equipamento

- Controle de correção manual

Repetitividade de processos

O Tartílope V3/V4 proporciona repetibilidade de processos, ou seja, o movimento executado uma vez poderá ser repetido com fidelidade quantas vezes forem necessárias.

Soldagem de Duto |

Soldagem Vertical |

O Tartílope V3/V4 apresenta todos os recursos necessários para a soldagem orbital de dutos com excelente qualidade.

Usando uma cinta bi-partida que pode ser facilmente acoplada ao duto, o equipamento executa a soldagem orbital de maneira automática e repetitiva. A execução da soldagem mecanizada garante qualidade, melhor acabamento, maior rapidez de execução e menor custo total em comparação com a soldagem manual. |

|

-

Versatilidade para executar diferentes tarefas de soldagem

-

Realiza soldagem orbital para construção de linhas dutoviárias

-

Realiza soldagem simples ou com tecimento (trapezoidal, triangular ou retangular)

-

Realiza o preenchimento de juntas em um único passe ou com redução de número de passes

-

Possibilita a programação prévia das variáveis de cada passe

-

Possibilita a programação das variáveis para diversos processos de soldagem

-

Possibilita a programação das trajetórias de soldagem utilizando até quatro eixos para deslocamento da tocha

-

Executa soldagem a partir de arquivo contendo parâmetros e trajetória pré-definida

A SPS desenvolve sistemas para soldagem, automação e instrumentação, atendendo setores como:

- Ensino e Pesquisa;

- Óleo e Gás;

- Construção Naval;

- Papel e Celulose;

- Mineração;

- Energia;

- Agricultura;

- Farmacêutica;

- Alimentícia;

- Bens de Consumo.