Tartílope V2F Orbital

Visão Geral

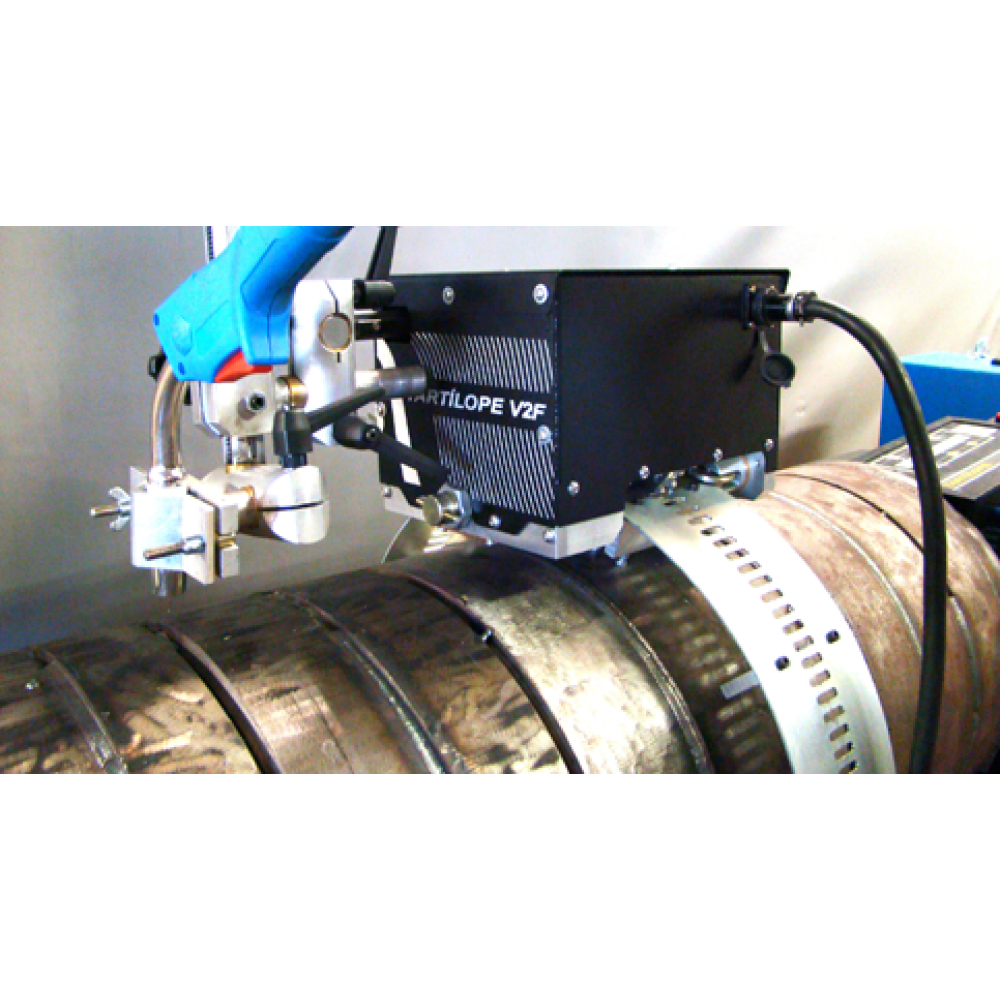

Tartílope V2F Orbital é um sistema de deslocamento automático de tocha que conta com as principais funcionalidades do Tartílope V2F, e utiliza uma cinta guia que permite a fixação do equipamento em peças cilíndricas possibilitand...Tartílope V2F Orbital é um sistema de deslocamento automático de tocha que conta com as principais funcionalidades do Tartílope V2F, e utiliza uma cinta guia que permite a fixação do equipamento em peças cilíndricas possibilitando a soldagem MIG orbital de dutos.

Características do Equipamento

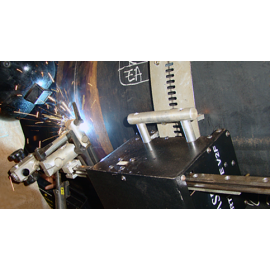

O sistema de soldagem MIG Orbital Tartílope V2F possibilita a realização de soldagem automatizada de dutos, proporcionando grande aumento de produtividade em relação à soldagem manual.

O MIG Orbital Tartílope V2F foi desenvolvido especialmente para atender às necessidades da indústria brasileira. É um equipamento de operação simples e construção robusta, adequado para o ambiente industrial.

O sistema foi desenvolvido ao longo de vários anos de experiência utilizando tecnologia de ponta proporcionando os recursos necessários para obtenção de soldas de elevada qualidade para os mais diferentes tipos de junta e materiais.

O sistema pode ser utilizado em diferentes diâmetros de tubos, sendo o diâmetro mínimo 12”, sem limitação para o diâmetro máximo.

- Módulo eletrônico microprocessado que processa e controla os movimentos

- Módulo trator com engrenamento para fixação na cinta guia

- Cinta com fixadores magnéticos ou por ventosas

- Módulo de fixação de tocha com ajustes manuais

- Controle remoto de programação

Repetitividade de processos

O Tartílope V2F Orbital proporciona repetibilidade de processos, ou seja, o movimento executado uma vez poderá ser repetido com fidelidade quantas vezes forem necessárias.

A SPS desenvolve sistemas para soldagem, automação e instrumentação, atendendo setores como:

- Ensino e Pesquisa;

- Óleo e Gás;

- Construção Naval;

- Papel e Celulose;

- Mineração;

- Energia;

- Agricultura;

- Farmacêutica;

- Alimentícia;

- Bens de Consumo.