Sistema para soldagem plasma com adição de pó metálico composto por fonte de soldagem, tocha e alimentador de pó. O equipamento tem aplicações em operações de revestimentos metálicos, produzindo resultados com alta qualidade superficial, baixa diluição e alta controlabilidade da poça de fusão.

Características do Processo PTA-P

A soldagem, como processo de recuperação de partes que sofreram perda de material, possui uma gama muito variada de possibilidades. O processo de soldagem Plasma com adição de pó permite a realização de revestimentos metálicos de alta qualidade superficial, baixa diluição e alta controlabilidade da poça de fusão.

Varias são as vantagens atribuídas ao processo, entre elas:

- O processo PTA-P pode alcançar uma diluição de 5%, muito inferior aos valores típicos de 20-25% obtidos com processos MIG/MAG e TIG.

- Maior facilidade para a produção de materiais de adição para diferentes finalidades experimentais misturando diferentes pós.

- Menor dependência entre a energia e a quantidade de material fundido em comparação com processos como o MIG/MAG.

- DIGIPLUS A7 PTA - Fonte de soldagem Plasma compatível com adição de pó, integra funções de controle de vazão de gás e controle do alimentador de pó

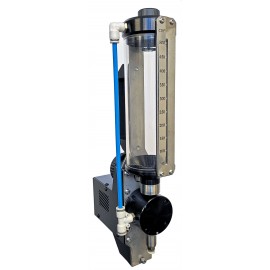

- ADP- Alimentador de pó para o processo PTA-P

- TOCHA PTA-P - Tocha de soldagem para o processo Plasma com adição de pó, com versões para uso manual ou mecanizado.

|

Como diferenciais, o equipamento congrega, em um único gabinete, as unidades de potência do arco principal e do arco piloto, o ignitor de alta frequência para o arco piloto, as válvulas eletrônicas de controle de vazão de gás de plasma e gás de arraste, a eletrônica de controle para o alimentador de pó, a unidade de controle microprocessado do sistema e a interface de configuração (interface-homem-máquina (IHM)). O software de controle possibilita, através da IHM, a regulagem eletrônica de todos os parâmetros do processo, incluindo a corrente do arco piloto, as vazões dos gases de plasma e de arraste de pó e a taxa de vazão mássica de pó. Juntamente à possibilidade de customizações, esta flexibilidade permite tanto ao setor industrial, como de pesquisa e desenvolvimento, uma ampla faixa de otimização do processo para cada aplicação específica. Em sua versão para aplicação automatizada, a DIGIPLUS A7 PTA pode, também através da IHM, controlar os manipuladores robóticos Tartílopes, constantes da linha da SPS, assim como outros sistemas de posicionamento e movimentação (por exemplo, mesas rotativas).

|

|

O ADP – Alimentador de Pó – confere alta performance na alimentação de consumíveis metálicos em pó. Pode ser utilizado com pós compatíveis com os padrões empregados no processo PTA-P no que diz respeito à forma e tamanho (granulometria). Valendo-se do princípio mecânico das esteiras transportadoras, um tambor dosador transfere o material contido no silo para a mangueira de transporte pneumático. A taxa de alimentação dos consumíveis de solda pode ser regulada tanto pela rotação do tambor como pela regulagem da altura entre o tambor e o canal de descarga do silo (GAP). O ADP – Alimentador de Pó – fornece alimentação contínua com boa regularidade, proporcionando soldas de alta qualidade. É ideal para aplicações industriais, sendo um equipamento robusto e com elevada durabilidade. |

|||||||||||

|

Dados Técnicos

|

||||||||||||

Tocha de soldagem para o processo PTA-P

|

A tocha PTA-P possui um design compacto e se diferencia pela presença de apenas um circuito de refrigeração a água, reduzindo o número de acessórios para as operações de revestimento ou união, contribuindo para a melhor mobilidade do sistema como um todo. Além disso, especial atenção foi dada ao projeto da montagem das peças, tornando a troca de consumíveis mais simples e rápida. Em uma de suas versões (sob consulta), permite a soldagem em posições fora da plana de maneira consistente, sem acúmulo de material de adição (pó metálico) em seu interior e com regularidade nos jatos de injeção de material à poça de fusão, mantendo menores valores de gás de arraste em relação a outros modelos do mercado.

|

|||||||||

|

Dados Técnicos

|

||||||||||

A SPS desenvolve sistemas para soldagem, automação e instrumentação, atendendo setores como:

- Ensino e Pesquisa;

- Óleo e Gás;

- Construção Naval;

- Papel e Celulose;

- Mineração;

- Energia;

- Agricultura;

- Farmacêutica;

- Alimentícia;

- Bens de Consumo.