Ferramenta Computacional para o Controle de Processos de Soldagem a Arco

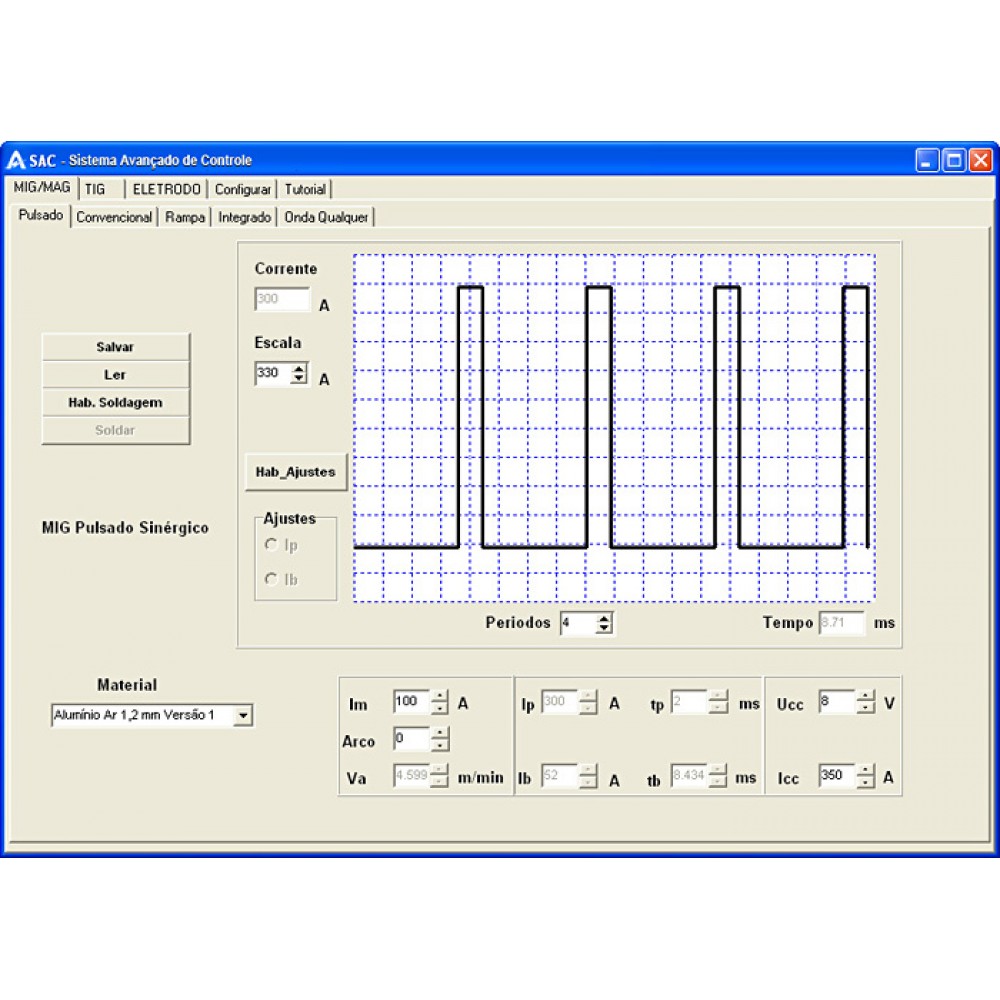

Sistema Avançado de controle da fonte de soldagem via micro-computador com interface gráfica

Desenvolvido para ambiente Windows, o SAC permite ao usuário controlar a fonte de soldagem usando um microcomputador via USB ou outros protocolos. O sistema possibilita a utilização de um grande número de processos de soldagem a arco, nas suas modalidades convencionais, e também em modalidade avançada como por exemplo, MIG pulsado, MIG pulsado térmico®, MIG modo misto, MIG curto circuito controlado, TIG pulsado, TIG alternado, Plasma pulsado, Plasma alternado.

Requisitos de sistema

|

|

Disposião Conceitual do Sistema Avançado de Controle

O sistema de controle da plataforma, como ilustra a figura, é; o responsável por decodificar os comandos dados pelo operador e agir diretamente sobre o "atuador do sistema". Por outro lado, o "sistema de aquisção" faz as leituras das variáveis de soldagem e as exibe novamente ao usuário por meio da interface da plataforma.

Entretanto, a disposição conceitual do SAC, quando implementada, adquire formatos condizentes com a tecnologia disponível no mercado e de domínio da equipe do LABSOLDA. Dessa maneira, a disposição física do Sistema Avançado de Controle, conta com dois microcomputadores que se comunicam por meio de suas portas seriais, responsáveis pela interface com o usuário, aquisição de sinais e controle dos processos. O atuador do sistema é uma fonte de soldagem.

Disposição física do Sistema Avançado de Controle

A utilização de duas CPU's para a implementação do SAC advém do fato de se necessitar de dois sistemas operacionais diferentes na atual concepção da plataforma, o Ms-Windows e o Ms-DOS. Como comentado no capítulo 2, apesar de fornecer ferramentas para tratamento de processos em tempo real altamente funcionais, o Ms-DOS não disponibiliza uma interface com o usuário versátil nos níveis de exigência do SAC. Por outro lado, o Ms-Windows, que fornece uma interface altamente intuitiva com o operador, dificulta intervenções substanciais de hardware, o que se vê extremamente necessário para o efetivo controle dos processos de soldagem.

Neste sentido, implementou-se a estrutura de controle do SAC sobre o programa "Oscilos v 3.1", um software de aquisição de sinais de soldagem também desenvolvido no laboratório e inteiramente estruturado sobre o sistema operacional Ms-DOS. Dessa maneira, todas as lógicas de intervenção sobre a fonte de soldagem ficaram agrupadas na "CPU 2", que faz tanto o controle dos processos de soldagem quanto a aquisição de sinais.

A interface de controle, no entanto, foi totalmente desenvolvida sobre a plataforma Ms-Windows, "CPU 1", permitindo o rápido acesso as variáveis de cada processo, bem como, flexibilizando o desenho de formas de onda de soldagem nas diferentes modalidades, utilizando-se das ferramentas gráficas que a plataforma em questão disponibiliza.

A utilização de duas unidades de processamento, apesar de inadequado do ponto de vista funcional e até econômico, permitiu o desenvolvimento paralelo do SAC, acelerando os progressos na sua implementação, além de criar o conceito de modularidade da plataforma, ou seja, a perfeita separação entre cada vertente do sistema, controle, aquisição, interface e atuação, o que o deixa apto a se moldar a novos conceitos tecnológicos.

A SPS desenvolve sistemas para soldagem, automação e instrumentação, atendendo setores como:

- Ensino e Pesquisa;

- Óleo e Gás;

- Construção Naval;

- Papel e Celulose;

- Mineração;

- Energia;

- Agricultura;

- Farmacêutica;

- Alimentícia;

- Bens de Consumo.