O sistema OrbiTIG é destinado à automatização da soldagem de tubos.

Sistema automático para soldagem orbital autógena (sem material de adição) de tubos de aço inox, aço carbono e ligas de titânio.

Aplicado para união de tubos de parede fina (até 2 mm de espessura) com diâmetro máximo de 3” (76,2 mm).

Solução ideal para automação da soldagem em situações onde os tubos não podem ser rotacionados e/ou em locais onde o espaço é restrito.

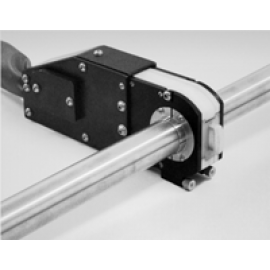

- Cabeçote de soldagem para tubos de diâmetro externo de até 3”

(recomendado para tubos com diâmetro entre 1” e 3”, mas pode ser utilizado também com tubos de menor diâmetro) - Acompanha adaptadores para tubos de 1”, 1.1/2”, 2”, 2.1/2” e 3”

(demais diâmetros sob encomenda) - Acompanha adaptador para soldagem de curvas

- Cabeçote de soldagem para tubos de diâmetro externo de até 1.1/4" (31,75 mm)

- Acompanha adaptadores para tubos de 1/2”, 1", 1.1/4"

(demais diâmetros sob encomenda) - Acompanha adaptador para soldagem de curvas

O sistema OrbiTIG-SPS opera com uma fonte de soldagem eletrônica transistorizada com regulagem totalmente digital.

Permite utilizar corrente pulsada e salvar os parâmetros de soldagem utilizados, produzindo soldas repetitivas.

O controle do movimento do cabeçote orbital é realizado pela própria fonte de soldagem, permitindo programação de diferentes parâmetros ao longo da soldagem.

Possui válvula com abertura e fechamento automático dos gases de proteção e de purga.

A fonte de soldagem integrada ao sistema de controle permite realizar adequada rastreabilidade de cada junta soldada.

A SPS desenvolve sistemas para soldagem, automação e instrumentação, atendendo setores como:

- Ensino e Pesquisa;

- Óleo e Gás;

- Construção Naval;

- Papel e Celulose;

- Mineração;

- Energia;

- Agricultura;

- Farmacêutica;

- Alimentícia;

- Bens de Consumo.