Características do Equipamento

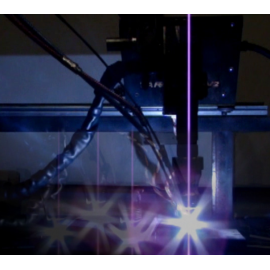

Sistema automático de abertura e controle do comprimento do arco para os processos de soldagem TIG e Plasma

O AVC é um equipamento que realiza o controle do comprimento do arco de maneira automática. Sua utilização é essencial quando se buscam aplicações automatizadas, de elevado desempenho e velocidade dos processos TIG e Plasma, já que a variação da distância eletrodo-peça nesses processos modifica de maneira acentuada as características do arco, podendo comprometer o resultado da soldagem. O equipamento possibilita ainda realizar a abertura do arco no processo TIG de maneira automática, possibilitando a aplicação desse processo em linha de produção robotizada.

- O AVC possui grande capacidade de adaptação em diferentes aplicações, sendo que a dinâmica de correção do comprimento do arco pode ser facilmente configurada de acordo com a utilização.

- O equipamento pode ser utilizado com corrente pulsada, corrente alternada, e também, em outras aplicações especiais.

Automação

O AVC pode funcionar como componente central do sistema de automação, integrando e controlando o funcionamento dos diferentes dispositivos.

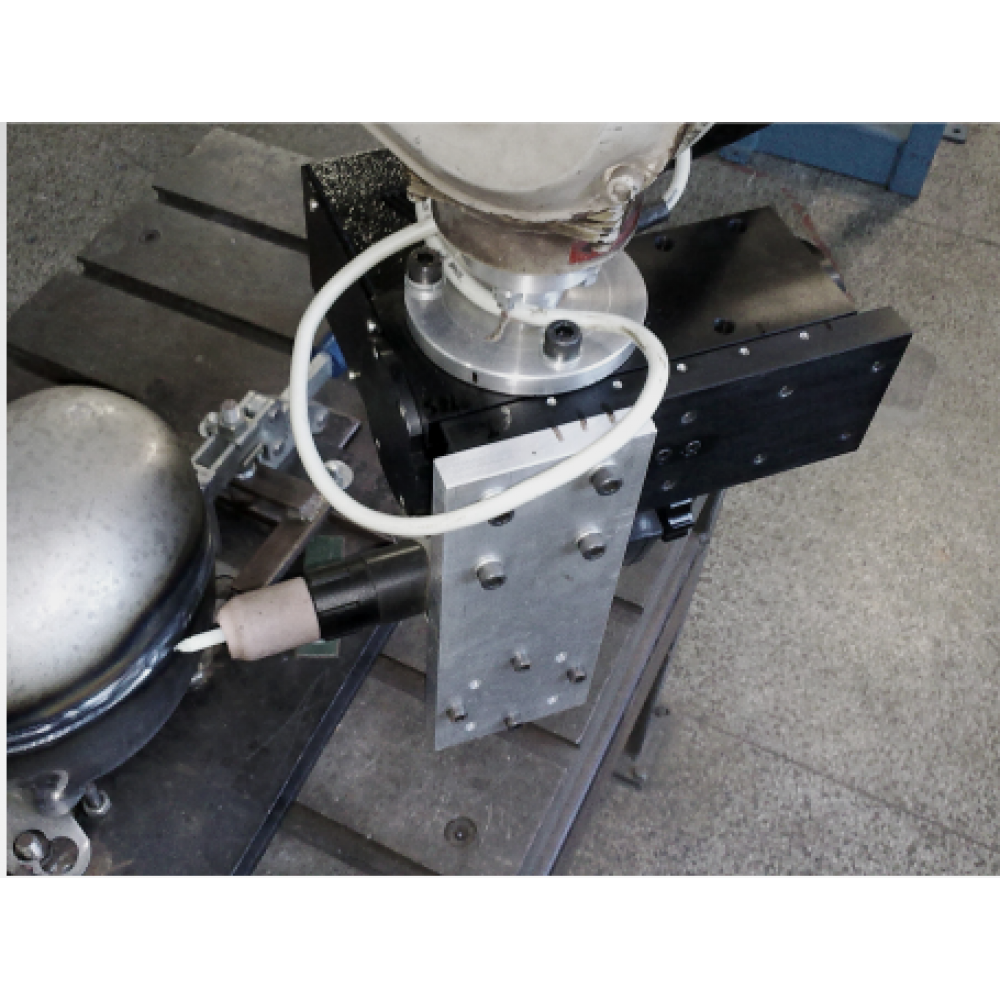

Atuador do sistemaO conjunto mecânico que realiza a movimentação da tocha de soldagem é construído em liga de alumínio de alta resistência, e os componentes principais como guias e fuso de esfera |

Unidade de controleO projeto eletrônico foi especialmente concebido para as operações de soldagem automatizadas, de modo que o sistema possui um total de 20 portas de comunicação (analógicas e digitais), permitindo grande capacidade de integração com fontes de soldagem, sensores, robôs, dispositivos de movimentação, CLP’s. |

MicrocontroladorA unidade de controle micro-processada utiliza o poderoso processador ARM A7 e possui uma interface homem máquina com display de LCD para configuração dos parâmetros. |

-

Processos: Soldagem TIG e Plasma com corrente contínua, pulsada ou alternada.

-

Corte a Plasma.

-

Curso útil do eixo de movimentação: 80 mm.

-

Leitura de tensão: ±80 V.

-

Ajuste da tensão de referência: 0,1 a 50,0 V.

-

Ajuste de sensibilidade (taxa de correção do comprimento do arco)

-

Possibilidade de ajustar o comprimento do arco durante a soldagem.

-

Possibilidade de salvar/ler os parâmetros do sistema em memória interna.

-

Possibilidade de adaptar o software do controlador conforme a necessidade do cliente.

A SPS desenvolve sistemas para soldagem, automação e instrumentação, atendendo setores como:

- Ensino e Pesquisa;

- Óleo e Gás;

- Construção Naval;

- Papel e Celulose;

- Mineração;

- Energia;

- Agricultura;

- Farmacêutica;

- Alimentícia;

- Bens de Consumo.